PhD from Christian Walter

by Christian Walter

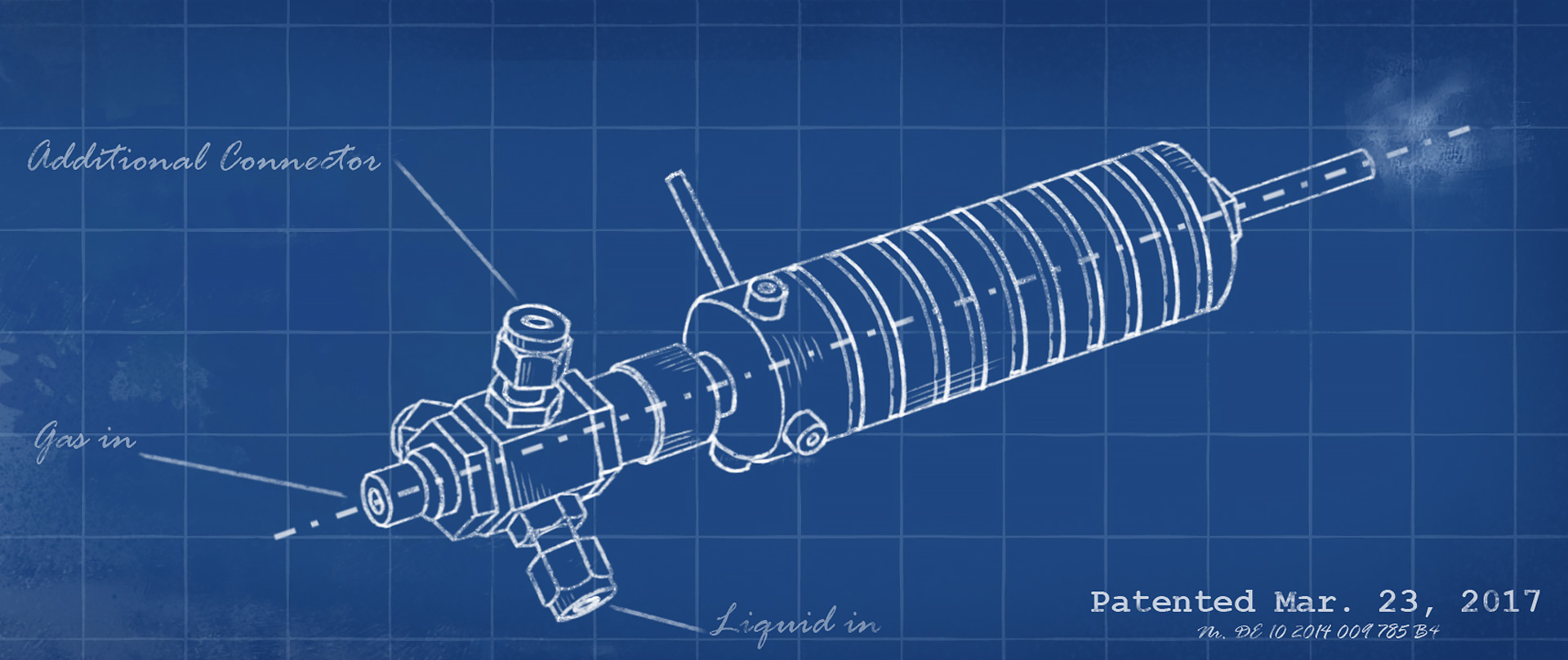

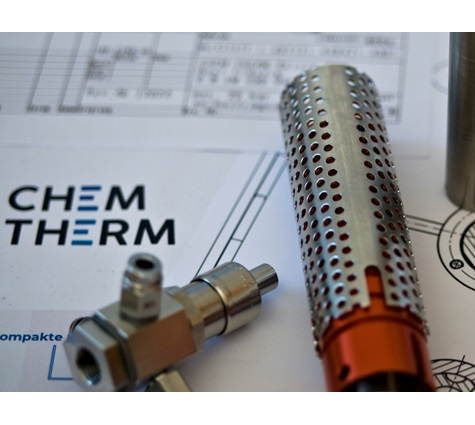

His presentation entitled “Analysis of wire mesh-based micro-heat exchangers for chemical reaction technology” focused on the presentation of the so-called "Thermogewebe" and the impressive investigation of evaporation dynamics using thermography.

A particular highlight of the evening was the traditional doctoral examination, which was conducted by former colleagues from the Institute of Chemical Process Engineering at the University of Stuttgart. In a series of entertaining games, he had to show that he can also score outside the scientific context.

For example, he used his many years of experience at Pause & Play to solve the escape room specially set up in the ICVT's archive. He was also able to impress with the production of a wire mesh on a model loom. Only in the tennis tic-tac-toe did he surprisingly have to admit defeat to Prof. Nieken.

The numerous guests created a great atmosphere and made the evening something special. Now the focus is back on ChemTherm - and perhaps the thermal fabrics will be used there again soon.

News

by Christian Walter

PhD from Christian Walter

Successfully passed exam

Last week the time had finally come: after several years of work, Christian Walter was able to convince the professors in charge of his dissertation with his doctoral presentation and subsequent examination.

by Zishan Mahmood

Year in review 2024

A year full of growth and innovation

With 2024 behind us, we look forward to the new calendar year of 2025 with great anticipation. 2024 has been an eventful and challenging year for us as a young company, demanding but also rewarding.

by Zishan Mahmood

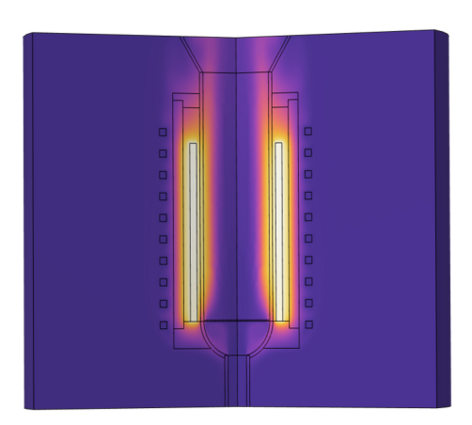

Master's thesis in cooperation with ChemTherm

Modeling and simulation of inductive heating of fixed-bed reactors

In cooperation with the Institute of Chemical Process Engineering and other industrial partners, we are delighted to welcome Tim Irlweck to our company.

by Raschid Abdel Aal

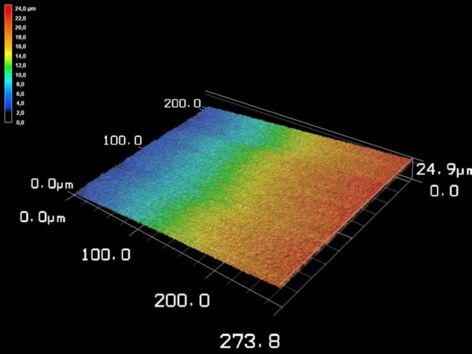

Cooperation with LightPulse LASER PRECISION

LightPulse uses ultrashort pulse lasers to work surfaces on a nanoscale. A wide variety of structures can be processed with this precise tool. The properties of the surface can be changed in a targeted manner. For example, laser-generated structures can be used to make a steel surface water-repellent (hydrophobic).