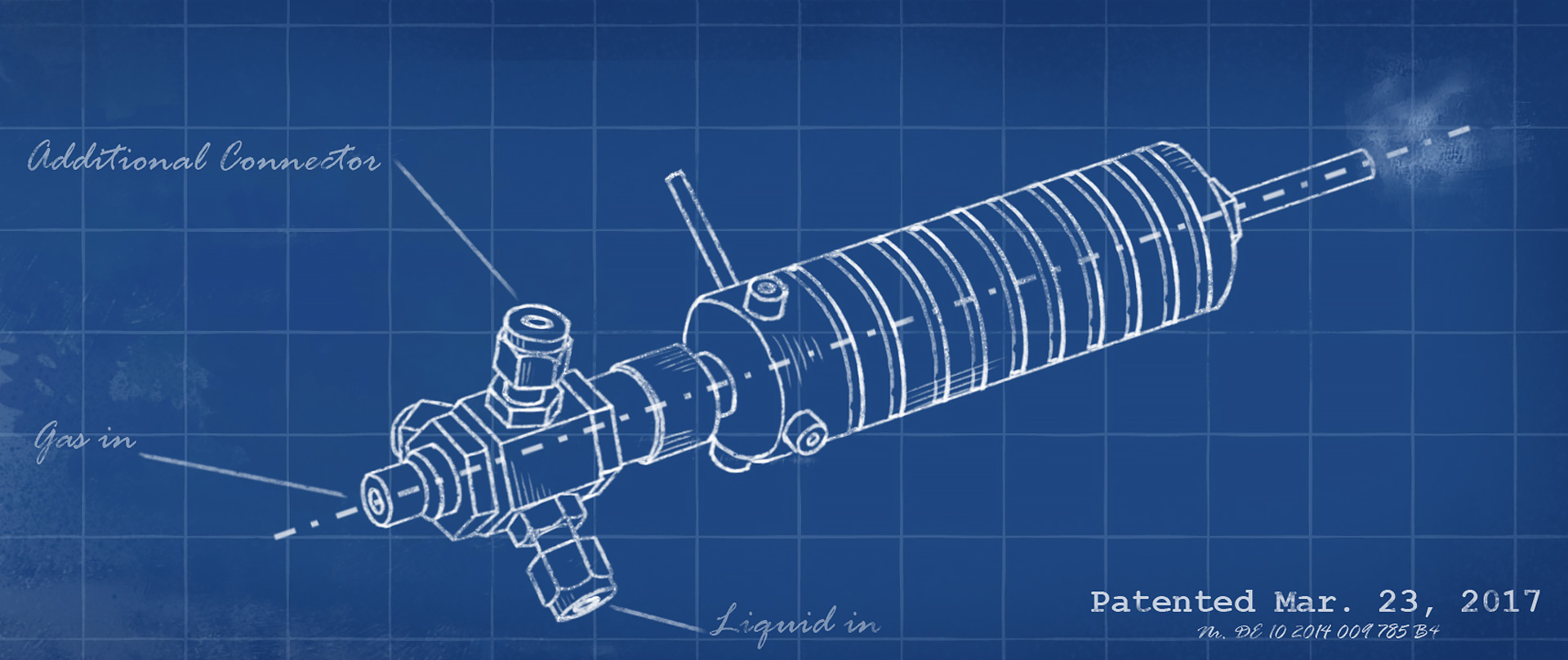

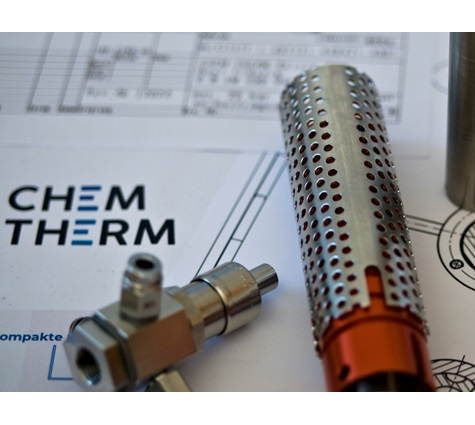

Combined vaporizer

The combined evaporator combines a total evaporator with a carrier gas supported evaporator. The optional gas supply can be used to generate directly undersaturated humidity mixtures or to realize a very compact direct supply of a water-gas mixture in the process.

Thanks to the combined evaporator, there are no longer any limits to humidity generation. Steam atmospheres from 0 - 100% are guaranteed. This evaporator enables precise, stable and energy efficent humidification in any position. To assure our evaporator systems can be used in any process each can be mounted directly on the process with a threaded fitting, from below, from the side or overhead.

Disruptive, heated, often long inlets are eliminated, the steam mixture is generated close to the process. Thanks to an integrated non-return valve, the evaporator system can also be used as a total evaporator. Even when used as a total evaporator, the combined evaporator keeps its benefits of a high heat input as well as a precise and pulsation-free vaporization.

Specifications

- Specifications

- Pressure range: Vacuum up to 50 bar

- Liquid: 0 – 600 g/h (H2O)

- Evaporation temperature: max. 400 °C

- Media- contact material 1.4571

- Up to 6 customer-specific connections for media/sensor technology

- Freely selectable installation position

- Completely dismountable

- Sealings: FKM/FFKM/metallic

- Chemically inert surface coating possible

Downloads:

Declaration of Conformity KV as download

Accessories

- Hochdruckpumpe für Präzise Dosierung

- Optimized control unit for flow-dependetnt power setting

- Variety of screw-in variants

- Connections, containers and filters for liquids

News

by Christian Walter

PhD from Christian Walter

Successfully passed exam

Last week the time had finally come: after several years of work, Christian Walter was able to convince the professors in charge of his dissertation with his doctoral presentation and subsequent examination.

by Zishan Mahmood

Year in review 2024

A year full of growth and innovation

With 2024 behind us, we look forward to the new calendar year of 2025 with great anticipation. 2024 has been an eventful and challenging year for us as a young company, demanding but also rewarding.

by Zishan Mahmood

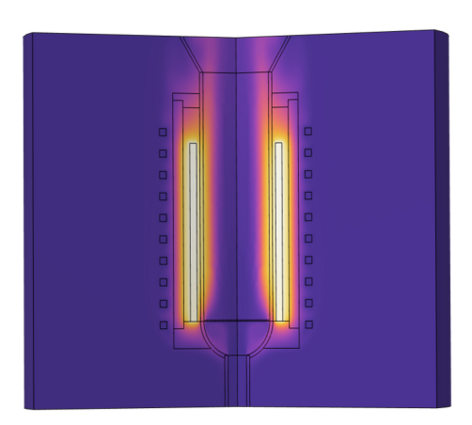

Master's thesis in cooperation with ChemTherm

Modeling and simulation of inductive heating of fixed-bed reactors

In cooperation with the Institute of Chemical Process Engineering and other industrial partners, we are delighted to welcome Tim Irlweck to our company.

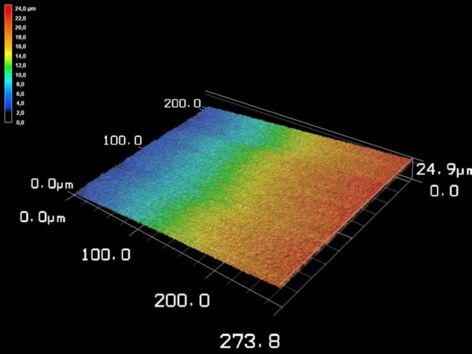

by Raschid Abdel Aal

Cooperation with LightPulse LASER PRECISION

LightPulse uses ultrashort pulse lasers to work surfaces on a nanoscale. A wide variety of structures can be processed with this precise tool. The properties of the surface can be changed in a targeted manner. For example, laser-generated structures can be used to make a steel surface water-repellent (hydrophobic).