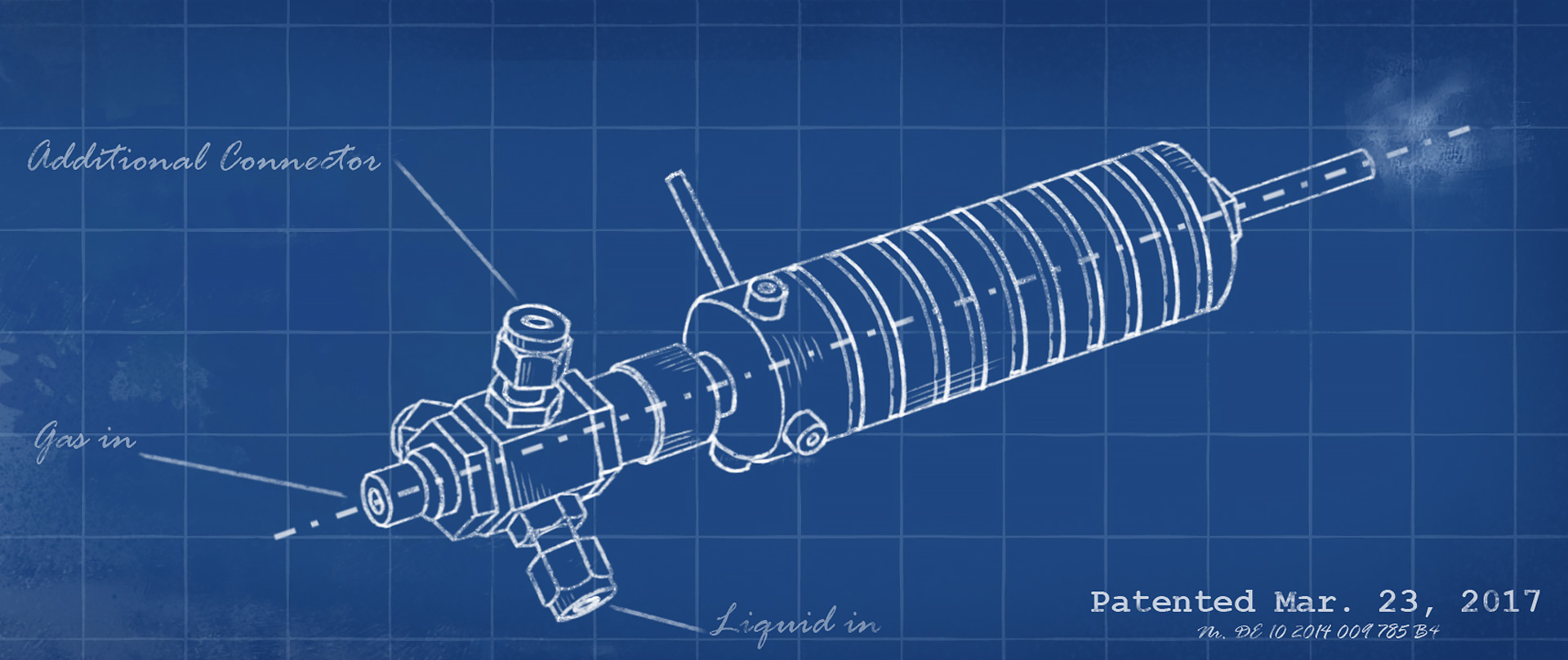

Total vaporizer

As a further evolution of the proven ICVT evaporator, our newly developed pulsation-free evaporators will set new standard in steam technology. With our total evaporator, we are able to provide a pulsation-free evaporation and high-precision dosing!

Thanks to our patented technology, the total evaporator offers impressive flexibility in terms of flow rates and pressure conditions - from 2 to 5,000 g/h at up to 100 bar. Perfect for complex applications in laboratories, pilot plants and research and development!

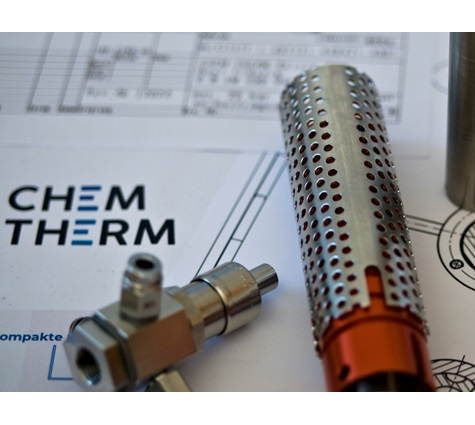

The high-quality stainless steel construction and fully dismountable design guarantees not only a long service life, but also easy maintenance and cleaning.

The high adaptability makes our total vaporizers the ideal choice for companies that require precise, reliable and energy efficent steam generation. Together with the wide operating range, they offer a sustainable and flexible solution for many projects in laboratories, pilot plants and R&D.

Specifications

- Pressure range: Vacuum up to 100 bar

- Liquid: 0.006 - 12 kg/h

- Evaporation temperature: max. 400 °C

- Medium-contact material 1.4571

- Customized media connections

- Freely selectable installation position

- Completely dismountable

- Sealings: FFKM/metallic

- Chemically inert surface coating possibe

Downloads:

Accessories

- High-pressure pump for precise dosing

- Optimized control unit for flow-dependent power setting

- Variety of screw-in variants

- Connections, containers and filters for liquids

News

by Christian Walter

PhD from Christian Walter

Successfully passed exam

Last week the time had finally come: after several years of work, Christian Walter was able to convince the professors in charge of his dissertation with his doctoral presentation and subsequent examination.

by Zishan Mahmood

Year in review 2024

A year full of growth and innovation

With 2024 behind us, we look forward to the new calendar year of 2025 with great anticipation. 2024 has been an eventful and challenging year for us as a young company, demanding but also rewarding.

by Zishan Mahmood

Master's thesis in cooperation with ChemTherm

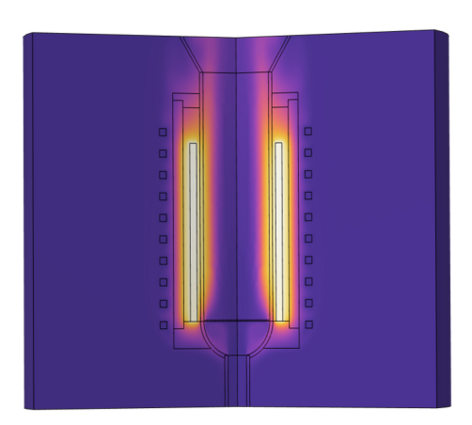

Modeling and simulation of inductive heating of fixed-bed reactors

In cooperation with the Institute of Chemical Process Engineering and other industrial partners, we are delighted to welcome Tim Irlweck to our company.

by Raschid Abdel Aal

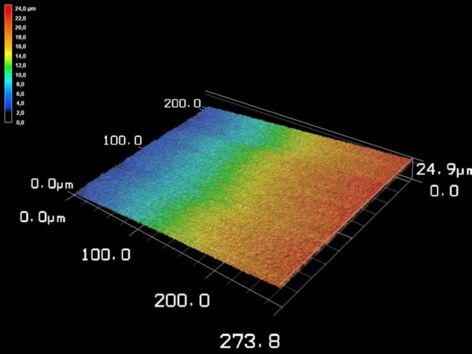

Cooperation with LightPulse LASER PRECISION

LightPulse uses ultrashort pulse lasers to work surfaces on a nanoscale. A wide variety of structures can be processed with this precise tool. The properties of the surface can be changed in a targeted manner. For example, laser-generated structures can be used to make a steel surface water-repellent (hydrophobic).