Application examples

Choosing the right evaporator is an important step in any application for laboratories, pilot plants or industrial plants to ensure that vapor dosing is optimally controlled. Chem-Therm has set itself the task of developing flexible and reliable evaporator systems to enable stable and pulsation-free evaporation for a wide range of processes. We are happy to take on all challenges in the field of vapor dosing that arise from our evaporators in your application areas, regardless of whether it is on a laboratory, pilot plant or industrial scale. Contact us and we will support you in designing a suitable evaporator!

APPLICATION CASE I: Water dosing in pilot plants

Accurate dosing of water in test systems is crucial in order to achieve reliable and reproducible results. Choosing the right evaporator for water dosing plays an important role in this. Due to their specific design our pulsation-free and energy efficient evaporators offer several advantages that lead to more precise water dosing.

Low-pulsation evaporators contribute to the stability of the water dosing process. By reducing pressure and volume fluctuations, a constant water flow is generated. This allows better control of the water dosing and minimizes the likelihood of unwanted variations during the experiment.

Large fluctuations in pressure or volume can lead to mechanical stress and premature wear of valves, piping and other parts of the system. By using low pulsation evaporators, such damage is avoided, increasing the lifetime of the experimental plant and reducing unexpected downtime.

APPLICATION CASE II: The plant time machine

Partner: Forschungszentrum Jülich

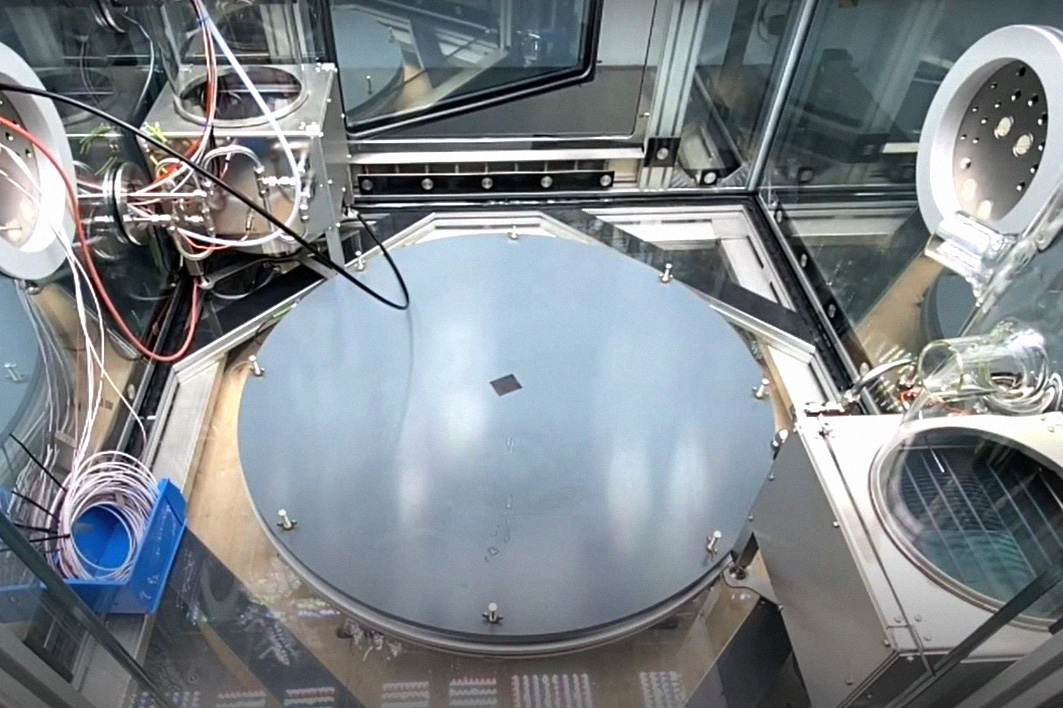

In the face of advancing climate change, agricultural research is facing major challenges. The large-scale experiment AgraSim (“Agricultural Simulator”), developed by the Jülich Institute of Bio- and Geosciences - Agrosphere and the Institute of Engineering, Electronics and Analytics - Engineering and Technology, is therefore investigating the adaptability of crops such as wheat, maize, barley and potatoes to future climatic changes. A kind of “time machine” has been developed for this purpose: In six agricultural simulation chambers, the influence of solar radiation, temperature, humidity, precipitation or CO₂ content of the air on the plants can be investigated under conditions that are as close to reality as possible.

A completely new evaporator variant was developed in close cooperation with the scientists and engineers at Forschungszentrum Jülich to precisely simulate the differences between the humidity levels in different regions and the day-night rhythm. The difficulty lies in dosing the water vapor into a cool air stream to create an undersaturated air-water vapor mixture. The initially uneven condensation of the water vapor dosed via a total evaporator could be reliably prevented by additionally injecting air into the evaporator over a wide range of volume flows.

ChemTherm's innovative evaporator technology made it possible to replace the initially planned solution with two separate total evaporators with a more efficient, directly integrable unit. Thanks to the efforts of our colleagues in Jülich, this type of evaporator is now also available as a combined evaporator for other research facilities, where it is highly valued for its performance and reliability.

We would like to thank Forschungszentrum Jülich for their confidence in our new development and look forward to further exciting projects in the field of climate research.

Further information:

https://www.fz-juelich.de/en/zea/zea-1/news/news/plant_time_maschine_agrasim

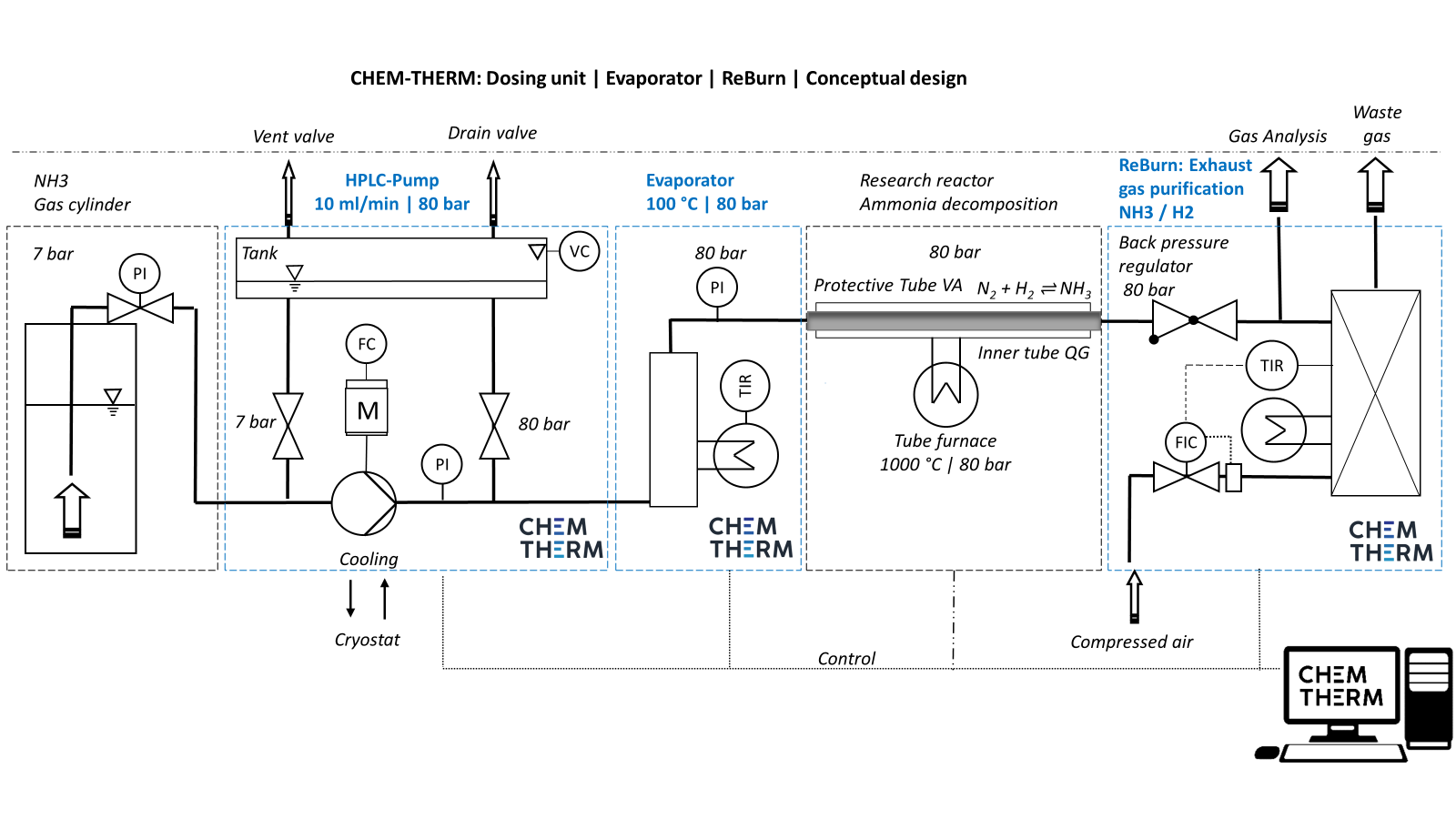

APPLICATION CASE III: Research on ammonia dehydrogenation with advanced ChemTherm components

Liquefied ammonia is an excellent storage and transportation medium for hydrogen. Thanks to the existing infrastructure and extensive experience in handling ammonia - whether as a refrigerant or in fertilizer production - the technology is ideally suited for use as a hydrogen carrier. As part of the BMBF's flagship projects, such as TransHyDE, various methods for the bound transportation and storage of hydrogen are being investigated. It is to be expected that ammonia will become an important component of the energy transition.

How does ammonia (NH₃) work as a transport medium for hydrogen (H₂)? Using electrical energy, pure hydrogen and nitrogen (N₂) can be converted from water and air into ammonia at the point of energy generation using the Haber-Bosch process:

2 NH₃ ⇌ N₂ + 3 H₂

The transportation of ammonia is simple, as it can be liquefied at room temperature under a pressure of less than 10 bar. Hydrogen can be recovered at the destination by dehydrating (splitting) ammonia. This process requires a catalyst, pressure and heat.

Research focus

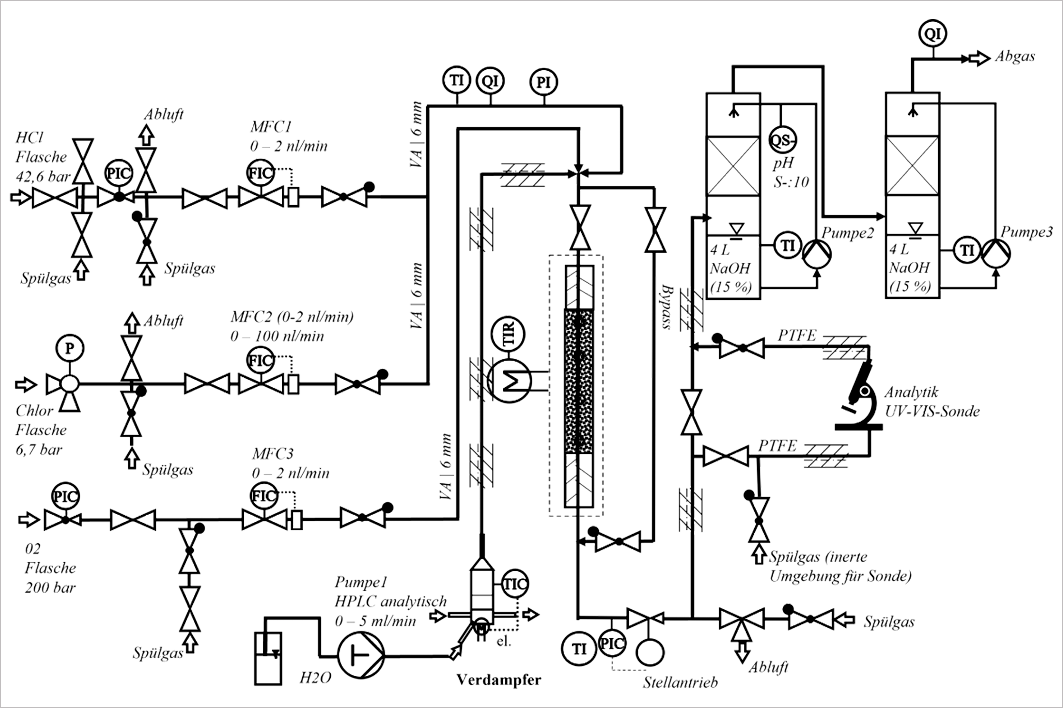

The research focus is on investigating the dehydrogenation of ammonia using suitable catalysts and materials. Nickel, iron, cobalt and ruthenium are mainly used as catalysts, whereby nickel and iron/cobalt are non-precious metals and ruthenium is a precious metal. Despite the established processes, many new questions arise: Which metals or precious metals - possibly also in combination - are best suited for the decomposition of ammonia? What effects do pressure and temperature have on the process? And how can maximum purity of the hydrogen obtained be achieved in order to minimize subsequent purification processes? Can higher temperatures in the reactor be realized through a suitable choice of materials and thus develop new reactor concepts?

Complete solutions from ChemTherm

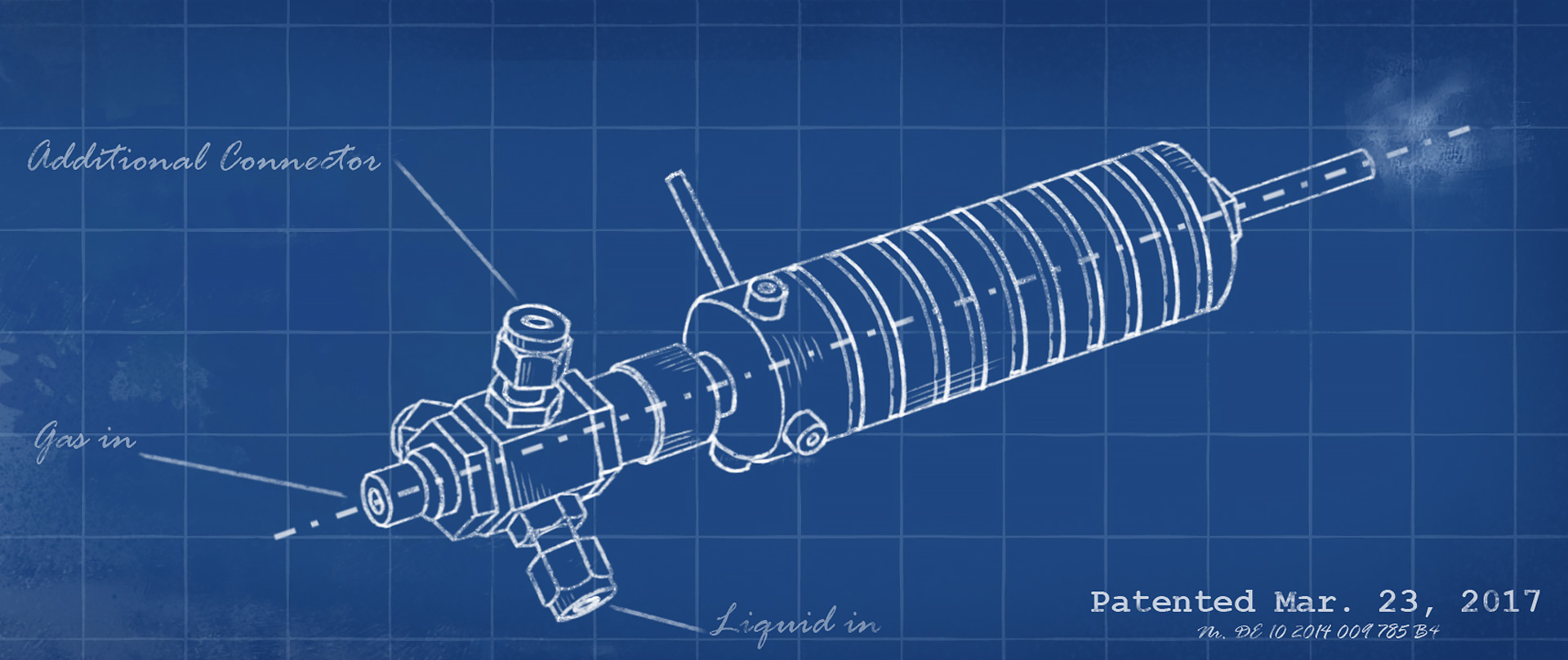

ChemTherm supplies the essential components for operating a ammonia dehydrogenation reactor. The flexible, pulsation-free evaporator enables precise dosing of ammonia and, with a wide operating range of 2 to 5000 g/h at pressures of up to 100 bar, offers numerous options for investigating ammonia splitting. Safe and environmentally friendly operation is ensured by a flameless exhaust gas purifier with a special combination of catalyst stages that guarantees safe neutralization of the reaction products.

ChemTherm not only provides the customer with the required plant components, but also advises on technical issues of all kinds and makes individual adjustments to the technical conditions on site. This allows the plant operator to concentrate fully on research without having to worry about planning and setting up the test plant. ChemTherm takes care of the provision and disposal of educts and products, which not only saves costs, but also valuable time.

News

by Christian Walter

PhD from Christian Walter

Successfully passed exam

Last week the time had finally come: after several years of work, Christian Walter was able to convince the professors in charge of his dissertation with his doctoral presentation and subsequent examination.

by Zishan Mahmood

Year in review 2024

A year full of growth and innovation

With 2024 behind us, we look forward to the new calendar year of 2025 with great anticipation. 2024 has been an eventful and challenging year for us as a young company, demanding but also rewarding.

by Zishan Mahmood

Master's thesis in cooperation with ChemTherm

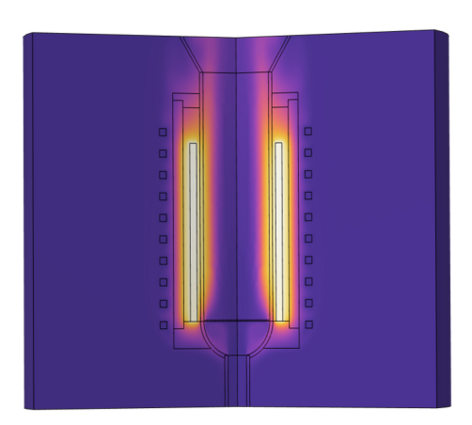

Modeling and simulation of inductive heating of fixed-bed reactors

In cooperation with the Institute of Chemical Process Engineering and other industrial partners, we are delighted to welcome Tim Irlweck to our company.

by Raschid Abdel Aal

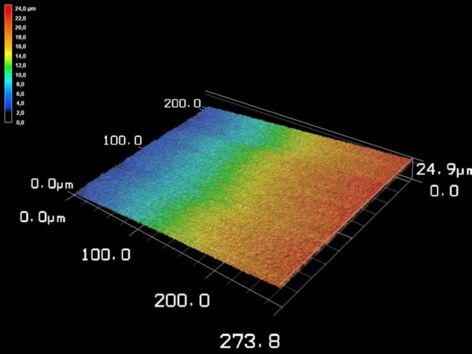

Cooperation with LightPulse LASER PRECISION

LightPulse uses ultrashort pulse lasers to work surfaces on a nanoscale. A wide variety of structures can be processed with this precise tool. The properties of the surface can be changed in a targeted manner. For example, laser-generated structures can be used to make a steel surface water-repellent (hydrophobic).