Welcome to Chem-Therm

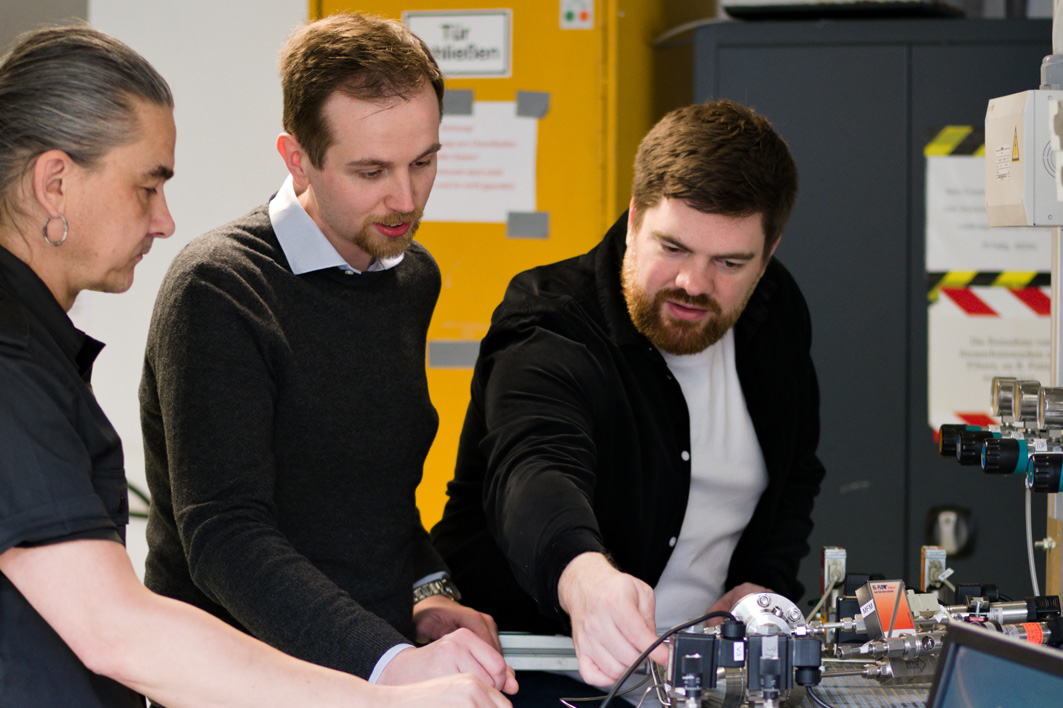

For over 15 years, the Institute of Chemical Engineering has been developing evaporator systems. The technologies developed and the experiences gained during this time are intended to be continued in a new company supported by a spin-off facilitated by the University of Stuttgart.

Since 2023, we have been part of the Technology Transfer Initiative GmbH as a Transfer and Founding Enterprise (TGU). TTI GmbH supports startup ventures and is a company of the University of Stuttgart. The newly founded TGU ChemTherm takes over the previous offerings of the Institute of Chemical Engineering and expands them with innovative and customer-specific solutions in the areas of steam generation and related fields of process engineering.

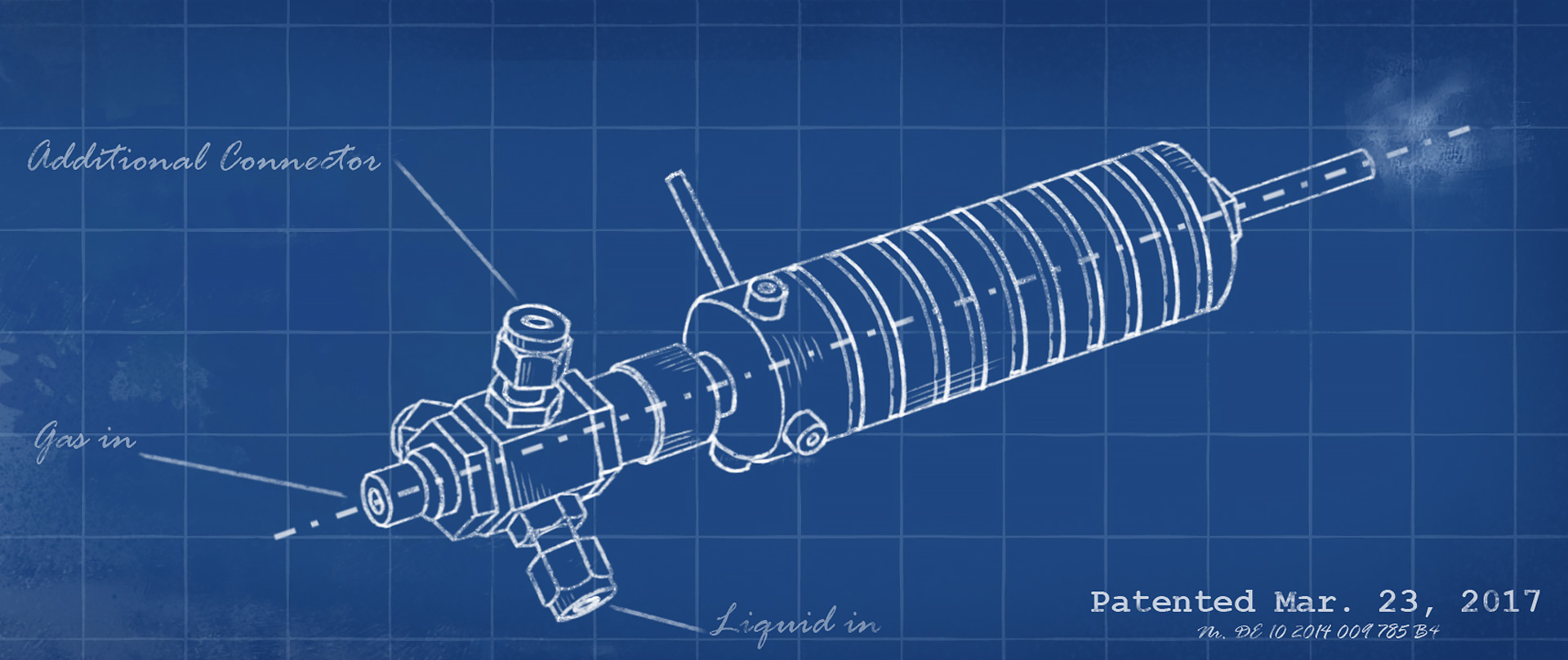

CHEM-THERM - THE SOLUTION FOR PRECISE VAPOR DOSING

High-precision steam dosing is a challenging task for numerous research and development applications. Chem-Therm has set itself the task of providing a solution for stable and pulsation-free steam dosing for a wide range of applications, such as laboratories, pilot plants or R&D.

Our patented second-generation ChemTherm evaporator concept stabilizes the pulsating momentum of flow boiling for continuous use. With this solution, we can guarantee a precise, fluctuation- and pulsation-free vapor flow even with the smallest throughputs.

Our Expertise

- Development of complete evaporator systems with precision dosing and ready-made control systems.

- Advice on the design and use of our evaporators for ideal vapor dosing.

- Production and quality testing of every evaporator, including certification.

- Versatile areas of application, in laboratories, pilot plants and in R&D

- Energy-efficent evaporator systems with high heat input

- Maintenance and service for optimum operating performance and adaptation to other applications.

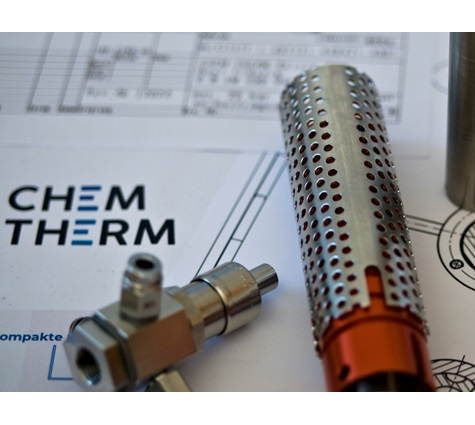

Thanks to its compact design, the evaporator system can be integrated into the plant close to the process. It is also possible to integrate the evaporator more effectively in space-limited applications than common concepts. The evaporator can be freely positioned - upright, horizontal, upside down - to guarantee a pulsation-free and precise vapor dosing in every process application.

The pulsation-free vaporization, even at minimum mass flows, enables fast, repeatable and efficient control over the volume flow. In combination with our calibrated precision pumps, this enables reliable vapor dosing with very high accuracy.

The user-friendly disassembly of the vaporizer allows for easy maintenance and cleaning of residues. The evaporator can be cleaned by the user on site with minimal effort.

Many applications and research projects in laboratories, pilot plants or the industry (e.g. ammonia reforming) require a flexible pressure range. The evaporator is designed for pressures between 0 and 100 bar, ensuring an application range from vacuum to high pressure.

In general, the evaporators offer a high resistance to corrosive fluids thanks to stainless steel surfaces in contact with the media and individually adapted seals enable a wide range of applications. It is also possible to extend the range of applications with various coatings.

Our innovative design avoids unnecessary cavities in the vaporizer, enabling fast fluid changes and short response times. In this way, all our evaporator systems enable a precise control and a fluctuation-free operation

VAPORIZER TECHNOLOGY

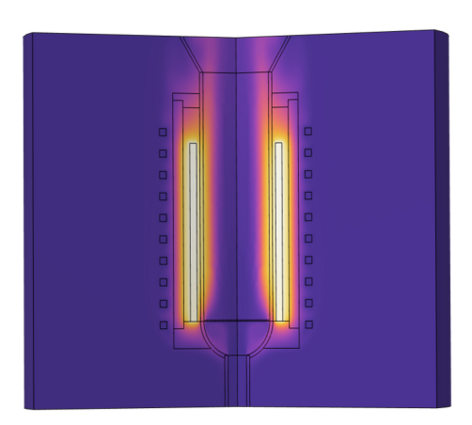

In many technical applications, stable vapor dosing with low pulsations and fast response times to load changes is required. Conventional vaporizers often reach their limits, especially with smaller quantities of liquid. The dynamics of vaporization quickly lead to pressure pulsations and liquid entrainment.

ChemTherm has set itself the task of ensuring robust and reliable production of small and large vapor flows. The patented evaporator concept enables controlled, precise and almost pulsation-free evaporation even without the use of a carrier gas. This makes our evaporators ideal for use in laboratories, pilot plants and R&D.

The most important features of our evaporator concept are:

- evaporation in narrow, structured channels

- the strict division into a cooled inlet area and a hot evaporation and superheating area

- the dismantlability of the design for cleaning purposes

- the flexible positioning and scalable execution of the ChemTherm evaporators.

The three variants of ChemTherm evaporators are optimized for different areas of applications:

- Total vaporizers for vapour generation with a wide range of pressures and capacities.

- Combination evaporators for the direct production of gas-vapor mixtures.

- Integratable, compact and pressure-stable inline evaporators

DEVELOPMENT SERVICES

In addition to the sale of our evaporators, we are also at your disposal for other services such as:

- Consulting and development of tasks (reactor concepts, high-temperature technology, waste heat utilization, construction of test plants) in the field of evaporation and heat transfer

- Individual support for research projects and measurement campaigns on our test facilities (conceptual design and testing of evaporation applications)

Questions or problems with:

Explosion protection? Unusual media? Higher pressures? Larger mass flows? Active cooling?

We are happy to respond to your special requirements!

Send a request!

Our Customers

News

by Christian Walter

PhD from Christian Walter

Successfully passed exam

Last week the time had finally come: after several years of work, Christian Walter was able to convince the professors in charge of his dissertation with his doctoral presentation and subsequent examination.

by Zishan Mahmood

Year in review 2024

A year full of growth and innovation

With 2024 behind us, we look forward to the new calendar year of 2025 with great anticipation. 2024 has been an eventful and challenging year for us as a young company, demanding but also rewarding.

by Zishan Mahmood

Master's thesis in cooperation with ChemTherm

Modeling and simulation of inductive heating of fixed-bed reactors

In cooperation with the Institute of Chemical Process Engineering and other industrial partners, we are delighted to welcome Tim Irlweck to our company.

by Raschid Abdel Aal

Cooperation with LightPulse LASER PRECISION

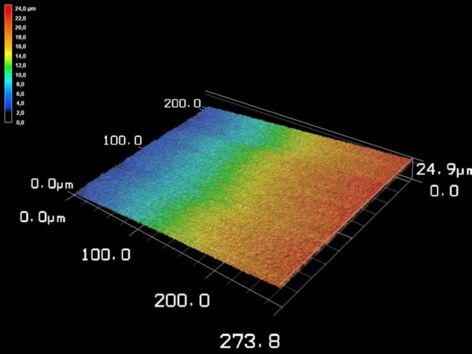

LightPulse uses ultrashort pulse lasers to work surfaces on a nanoscale. A wide variety of structures can be processed with this precise tool. The properties of the surface can be changed in a targeted manner. For example, laser-generated structures can be used to make a steel surface water-repellent (hydrophobic).