Chem-Therm – Die Lösung für präzise Dampfdosierung

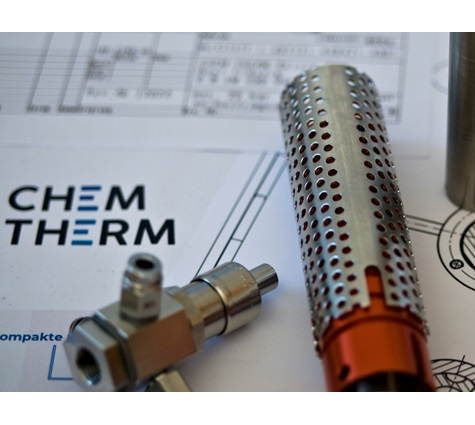

Eine hochpräzise, pulsationsarme und schwankungsfreie Dampfdosierung ist eine herausfordernde Aufgabe für zahlreiche Anwendungen in Labor- sowie Forschungs- und Entwicklungsaufgaben. Als Spin-Off des Instituts für Chemische Verfahrenstechnik der Universität Stuttgart, bieten wir basierend auf mehr als 15 Jahren Erfahrung erprobte Lösungen für die Bereitstellung von Dampf oder die Erzeugung von Gas-Dampf-Gemischen an.

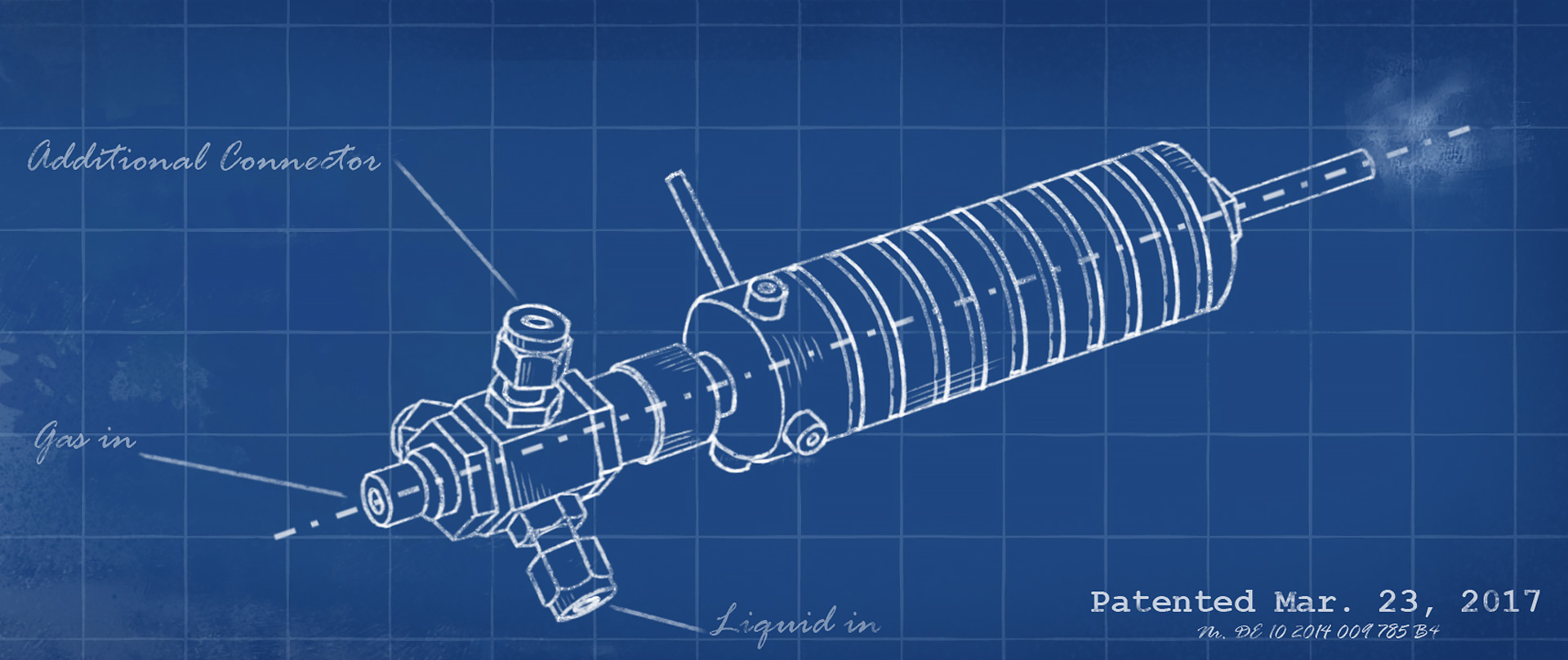

Unser patentiertes ChemTherm Verdampferkonzept der zweiten Generation stabilisiert die pulsierende Eigendynamik des Strömungssiedens für den kontinuierlichen Einsatz. Mit dieser Lösung erhalten Sie auch bei kleinsten Durchsätzen einen präzisen, stabilen und pulsationsfreien Dampfstrom.

Unsere Expertise

- Entwicklung kompletter pulsationsfreier Verdampfersysteme mit Präzisionsdosierung und konfektionierten Regelsystemen.

- Beratung, bei Auslegung und Einsatz unserer Verdampfer für präzise Dampfdosierung sowie Befeuchtung von Prozessgasen.

- Fertigung und Qualitätsprüfung, jedes Verdampfers inklusive Zertifizierung.

- Vielseitige Einsatzbereiche, in Labor- und Technikumsanlagen, sowie in der Forschung und Entwicklung.

- Energieeffiziente Verdampfersysteme mit hohem Wärmeeintrag

- Wartung und Service, für optimale Betriebsleistung und Anpassungen auf weitere Anwendungen.

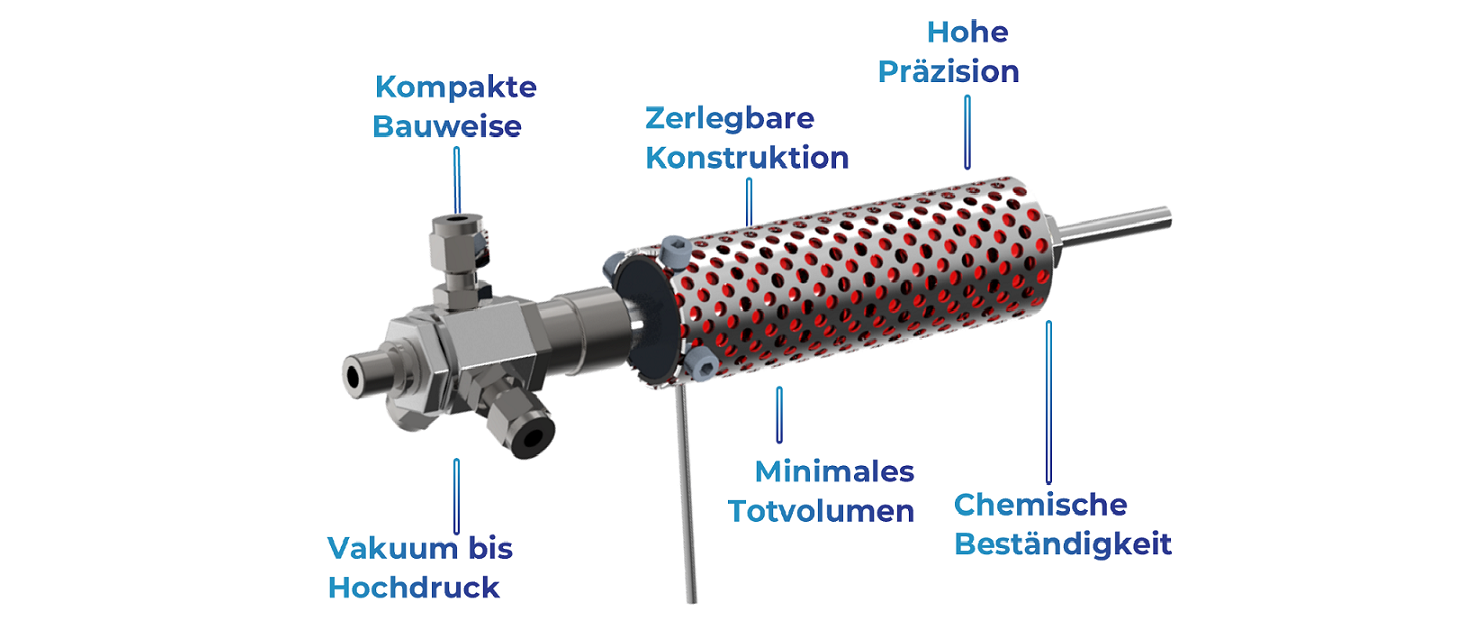

Vorteile unserer Chem-Therm Verdampfer

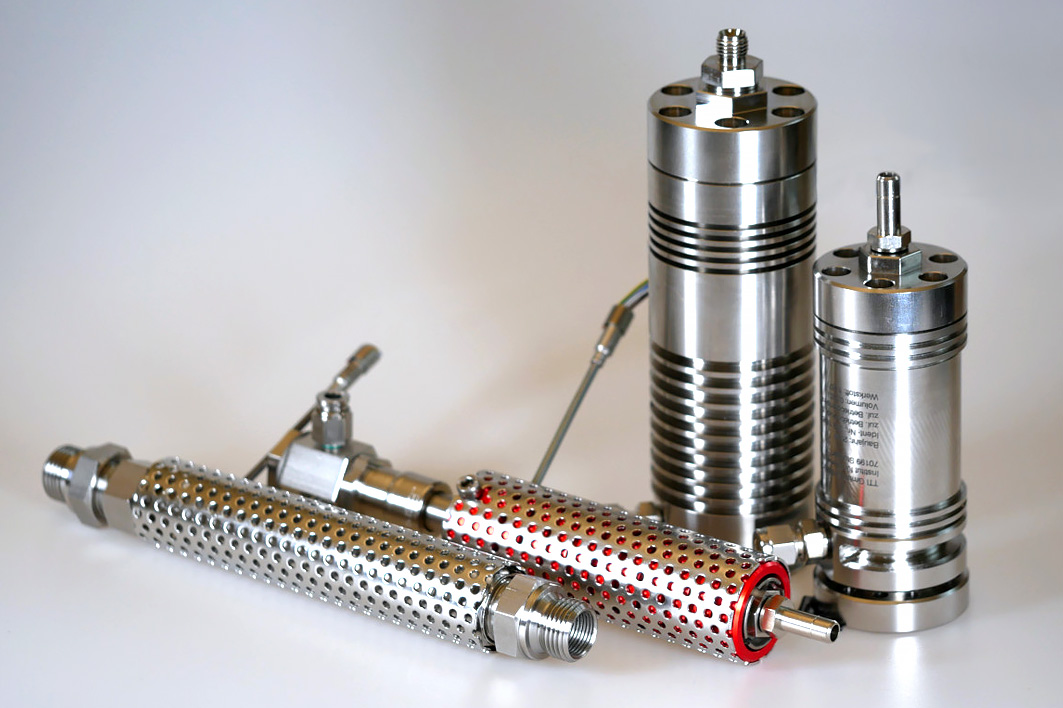

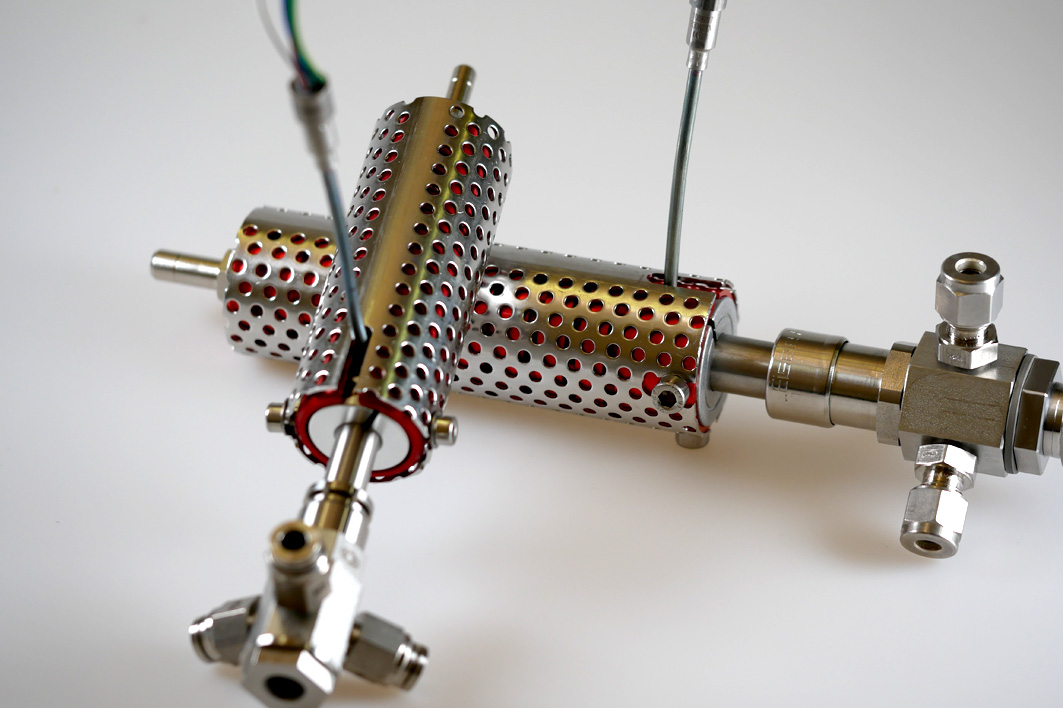

Durch die kompakte Bauweise können unsere Verdampfersysteme prozessnah in die Versuchsanlage integriert werden. Außerdem ist es möglich sowohl unsere Totalverdampfer, als auch unsere kombinierten Verdampfer in platzlimitierten Anwendungen effektiver zu integrieren als bisherige Konzepte. Eine freie Positionierung - stehend, liegend, kopfüber all unserer Verdampfersysteme ist möglich, wodurch eine optimale und pulsationsarme Dampfdosierung in jeder Prozessanwendungen garantiert werden kann.

Die pulsationsfreie Verdampfung auch bei minimalen Massenströmen ermöglicht eine schnelle, wiederholbare und effiziente Kontrolle über den Volumenstrom. In Kombination mit unseren kalibrierten Präzisionspumpen kann dadurch eine verlässliche Dampfdosierung mit sehr hoher Genauigkeit ermöglicht werden.

Die anwenderfreundliche Zerlegung des Verdampfersysteme ermöglicht eine einfache Wartung und Reinigung von Rückständen. Die Reinigung des Totalverdampfers als auch des kombinierten Verdampfers kann vom Nutzenden vor Ort unter minimalen Aufwand selbstständig durchgeführt werden.

Viele Anwendungen und Forschungsprojekte im Labor, Technikum oder der Industrie(z.B. Ammoniakreformierung) erfordern einen flexiblen Druckbereich. Der Verdampfer ist für Drücke zwischen 0 und 100 bar konzipiert, wodurch ein stabiler Einsatzbereich vom Vakuum bis zum Hochdruck gewährleistet wird.

Generell bieten unsere Verdampfer eine hohe Resistenz gegen korrosive Fluide und ermöglichen durch medienberührende Edelstahlflächen und individuell angepasste Dichtungen ein breites Einsatzspektrum. Zusätzlich besteht die Möglichkeit den Anwendungsbereich durch verschiedene Beschichtungen zu erweitern um spezifische Anwendungsbereiche zu ermöglichen.

Durch unser innovatives Design vermeiden wir unnötige Hohlräume im Verdampfer dadurch werden schnelle Fluidwechsel und kurze Ansprechzeiten ermöglicht. Auf diese Weise versichern all unsere Verdampfersysteme eine präzise Steuerung und einen schwankungsfreien Betrieb.

Verdampfer Technologie

In vielen technischen Anwendungen ist eine schwankungsfreie und präzise Dampfdosierung mit geringen Pulsationen und schneller Reaktionszeit auf Lastwechsel erforderlich. Insbesondere bei kleineren Flüssigkeitsmengen kommen herkömmliche Verdampfer häufig an ihre Grenzen, da die Dynamik der Verdampfung rasch zu Druckpulsationen und Flüssigkeitsmitnahme führen kann.

ChemTherm hat es sich zur Aufgabe gemacht eine robuste und zuverlässige Erzeugung kleiner und großer Dampfströme zu gewährleisten. Unser innovatives und patentierte Verdampferkonzept hebt sich von herkömmlichen Verdampfern ab und ermöglicht auch ohne Einsatz von Trägergas eine kontrollierte und nahezu pulsationsfreie Verdampfung. Dadurch sind unsere energieeffizienten Verdampfer optimal geeignet für den Einsatz im Labor, Technikum und der Forschung und Entwicklung.

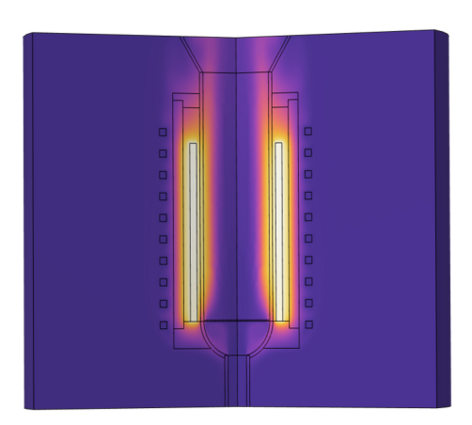

Die wichtigsten Merkmale unseres Verdampferkonzepts sind:

- die Verdampfung in engen, strukturierten Kanälen

- die strikte Unterteilung in einen gekühlten Zulaufbereich und einen heißen Verdampfungs- und Überhitzungsbereich

- die Zerlegbarkeit der Konstruktion zu Reinigungszwecken

- die flexible Positionierung und skalierbare Ausführung der ChemTherm Verdampfersysteme.

Die drei Varianten der pulsationsarmen Verdampfer von ChemTherm sind auf verschiedene Einsatzbereiche optimiert:

- Totalverdampfer zur Dampferzeugung mit größtem Druck- und Leistungsspektrum.

- Kombinierter Verdampfer zur direkten Erzeugung von Gas-Dampf-Gemischen.

- Inlineverdampfer als integrierbare Lösung besonders kompakt und druckstabil.

Entwicklungsdienstleistungen

Zusätzlich zum Verkauf unserer Verdampfersysteme stehen wir Ihnen auch bei weiteren Dienstleistungen zu Verfügung:

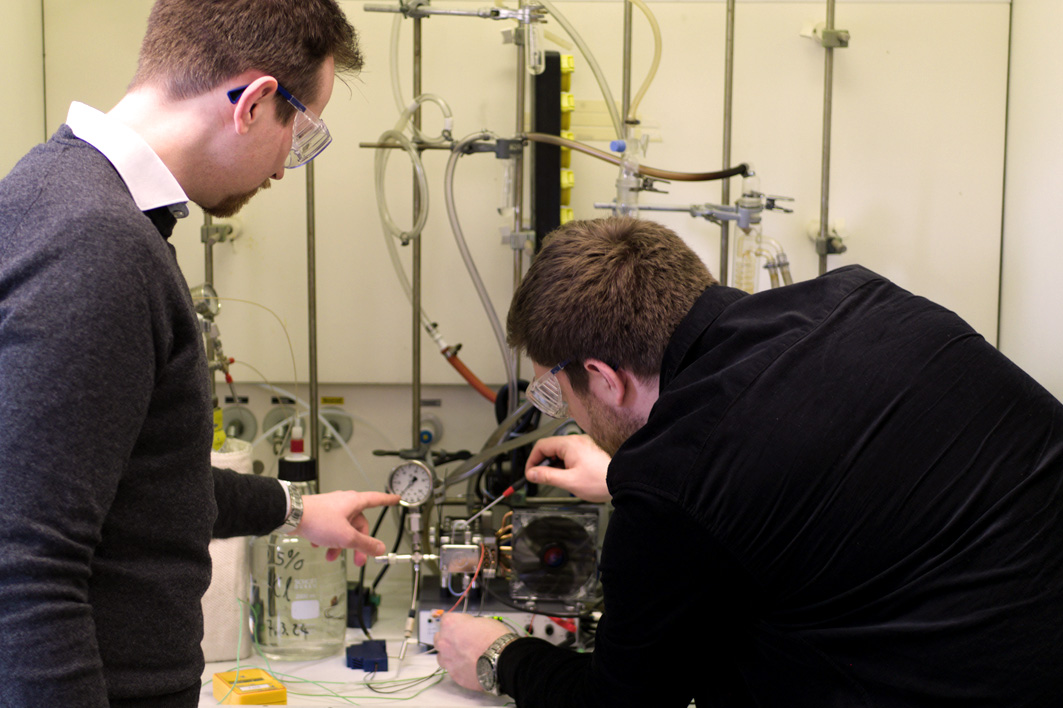

- Beratung und Entwicklungen bei Aufgabenstellungen (Reaktorkonzepte, Hochtemperaturtechnik, Abwärmenutzung, Bau von Versuchsanlagen) im Bereich der Verdampfung und Wärmeübertragung

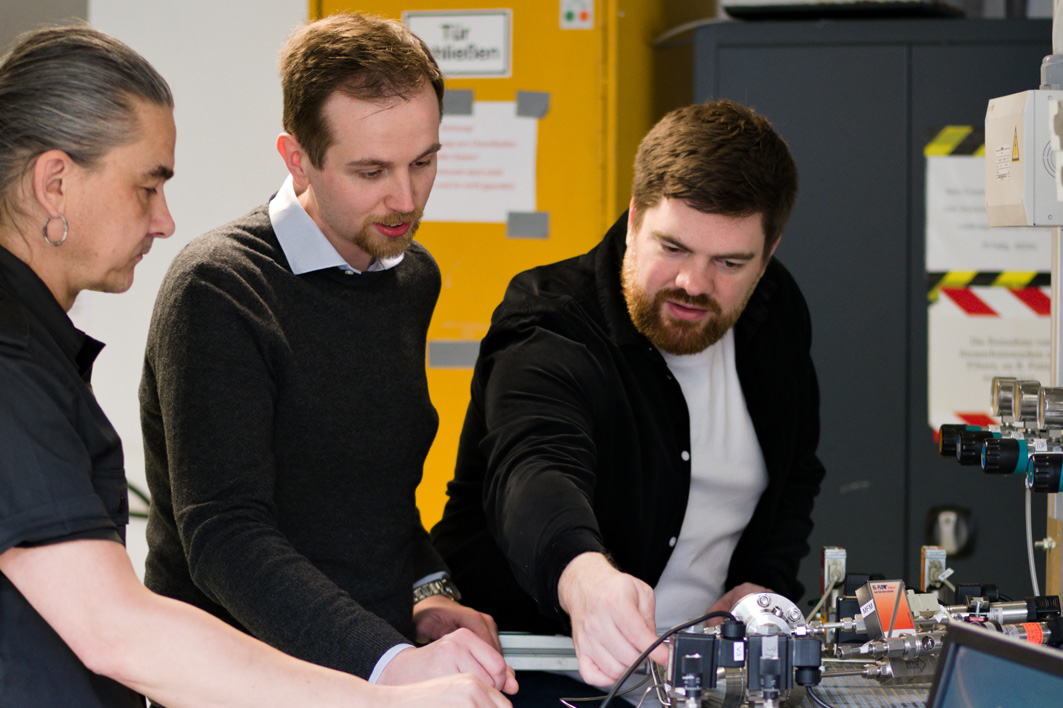

- Individuelle Unterstützung bei Forschungsprojekten und Messkampagnen auf unseren Versuchsanlagen (Konzeptionierung und Erprobung von Verdampfungsanwendungen)

Fragen oder Probleme mit:

Ex-Schutz? Ungewöhnlichen Medien? Höheren Drücke? Größeren Massenströmen? Der Aktiven Kühlung?

Wir gehen gerne auf Ihre besonderen Anforderungen ein!

Unsere bisherige Kunden

Aktuelles

von Christian Walter

Promotion von Christian Walter

Erfolgreich bestandene Prüfung

Vergangene Woche war es endlich soweit: Nach mehreren Jahren Arbeit konnte Christian Walter mit seinem Promotionsvortrag und der anschließenden Prüfung die zuständigen Professoren von seiner Dissertation überzeugen.

von Zishan Mahmood

Jahresrückblick 2024

Ein Jahr voller Wachstum und Innovation

Das Jahr 2024 liegt hinter uns, und wir blicken voller Vorfreude in das neue Kalenderjahr 2025. Für uns als junges Unternehmen war 2024 ein ereignisreiches und herausforderndes Jahr, das uns viel abverlangt, aber auch viele Erfolge beschert hat.

von Zishan Mahmood

Masterarbeit in Kooperation mit ChemTherm

Modellierung und Simulation der induktiven Beheizung von Festbettreaktoren

In Zusammenarbeit mit dem Institut für Chemische Verfahrenstechnik sowie weiteren Industriepartnern freuen wir uns, Tim Irlweck in unserem Unternehmen willkommen zu heißen.

von Christian Walter

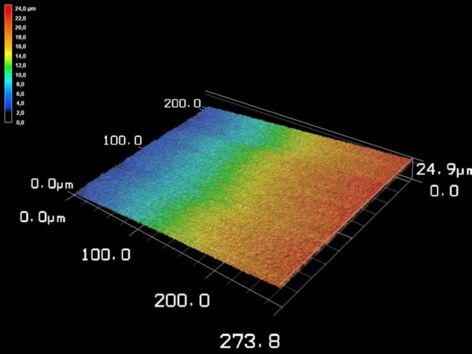

Kooperation mit LightPulse LASER PRECISION

LightPulse arbeitet mit Ultrakurzpuls-Lasern Oberflächen auf Nanoskala. Mit diesem präzisen Werkzeug lassen sich verschiedenste Strukturen bearbeiten. Die Eigenschaften der Oberfläche können dabei gezielt verändert werden. So kann beispielsweise mit lasergenerierten Strukturen eine Stahloberfläche wasserabweisend (hydrophob) gestaltet werden.